MAIN FUNCTIONS:

- Punching

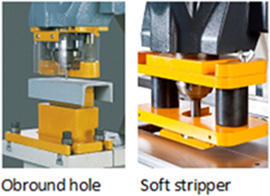

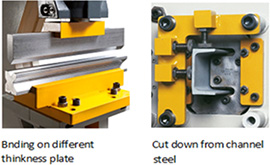

Full range of universal punches and dies are available.unique style allows for large angle iron punching and large channel punching.Large viewing window on stripper swing away design for ease of operation.large two piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change. - Shearing

Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar,channel/beam cutting. Large strong guarding for max safety. The angle shear has the ability to cut angle at 45°both top and bottom leg.This gives the operator the ability to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity. Easily adjustable hold-down device for accurate plate cutting.large 15″squaring arm with inlaid scale.Special anti-distorted blade for quality cutting.Lower blade has four usable edges.There is screw allow for gap adjust no shim needed. - Notching

Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.The notching section of this hydraulic iron worker is perfect for notching out metal plate, angle iron and much more. The notching station also has an oversized table with material stops. This section of the machine can also be outfitted with the optional vee notcher. - Bending

Also bend the plate below 500mm. All the components of Machine are of the highest quality in their safty, function, capability and maintenance

TECHNICAL PARAMETERS:

| No | Function | Item | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 |

| 1 | Shearing plate | Shearing pressure(Kn) | 600 | 900 | 1200 | 1600 | 2000 | 2500 |

| Shearing size of one stroke(mm) | 16*250 | 20*330 | 25*330 | 30*355 | 35*400 | 40*400 | ||

| Max.cutting size(mm) | 8*400 | 10*480 | 16*600 | 20*600 | 25*700 | 30*750 | ||

| Length of blade (mm) | 400 | 485 | 600 | 610 | 700 | 760 | ||

| Blade angle (°) | 7 | 8 | 8 | 8 | 8 | 8 | ||

| 2 | Shearing bar | Square bar (mm) | 40 | 45 | 50 | 55 | 60 | 65 |

| Round steel (mm) | 45 | 50 | 60 | 65 | 70 | 80 | ||

| Channel steel (mm) | 126 | 160 | 200 | 280 | 300 | 320 | ||

| I-beam steel(mm) | 126 | 160 | 200 | 280 | 300 | 320 | ||

| 90°shearing of equal-angle bar(mm) | 125*12 | 140*12 | 160*14 | 180*16 | 200*18 | 200*20 | ||

| 45°shearing of equal-angle bar(mm) | 70*8 | 50*5 | 80*7 | 60*6 | 100*10 | 120*16 | ||

| 90°shearing of T-bar(mm) | 120*12 | 140*12 | 160*14 | 180*16 | 160*14 | 180*16 | ||

| 45°shearing of T-bar(mm) | 60*8 | 70*10 | 80*10 | 80*10 | 80*10 | 80*10 | ||

| 3 | Notching | Thickness (mm) | 8 | 10 | 12 | 16 | 16 | 18 |

| Width (mm) | 57 | 57 | 57 | 60 | 60 | 120 | ||

| Depth (mm) | 100 | 100 | 100 | 100 | 100 | 120 | ||

| 4 | Punching | Punching pressure (t) | 60 | 90 | 120 | 160 | 200 | 250 |

| Thickness (mm) | 16 | 20 | 25 | 30 | 35 | 40 | ||

| Max punching diameter (mm) | 25 | 30 | 35 | 35 | 40 | 40 | ||

| Throat depth (mm) | 300 | 355 | 400 | 600 | 600 | 600 | ||

| Max length of cylinder stroke (mm) | 80 | 80 | 80 | 80 | 80 | 80 | ||

| Number of stroke | 12 | 12 | 10 | 10 | 10 | 10 | ||

| 5 | Plate strength (Mpa) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

| 6 | Motor power (Kw) | 4 | 5.5 | 7.5 | 11 | 15 | 18 | |

| 7 | Dimension (LXWXH) | 1640*730*1770 | 1860*800*1900 | 2355*960*2090 | 2680*1040*2300 | 2900*1300*2650 | ||

| 8 | N.W (KG) | 1700 | 2300 | 4300 | 6800 | 8000 | ||

Application for punch station